You have a unique design for a perfume bottle. But turning that idea into a real product seems complicated. Our clear process makes it simple and straightforward for you.

We turn your vision into a real glass bottle in two main ways. For a completely new shape, we create a custom mold from your sample or design file. For existing bottles, we add your unique color or logo.

You have a vision for a bottle that will make your brand stand out. But how does that idea become a physical product you can hold in your hands? The journey from a concept to a finished bottle is a detailed and precise one. I want to walk you through exactly how we do it at Lixi Packaging. Let's start with the most creative option: making a brand-new bottle shape just for you.

What if you need a completely new bottle shape?

Your brand is unique, and stock bottles just don't capture its essence. Creating a custom mold sounds expensive and difficult. We have a streamlined process that makes it achievable.

If our existing molds don’t work for you, we create a new one. This process usually requires a minimum order of 50,000 bottles. You can start by giving us a physical sample or a design file.

Creating a bottle that is exclusively yours is the ultimate way to define your brand. This path is for when you have a specific shape in mind that you can't find anywhere else. I remember working with a new niche brand that wanted a bottle shaped like a specific crystal. It was a challenge, but seeing the final product on the shelf was incredibly rewarding for both of us. The process requires a larger commitment, like a minimum order of 50,000 pieces for a standard 200g bottle, because we are building the tools from scratch just for you. It all starts with your idea.

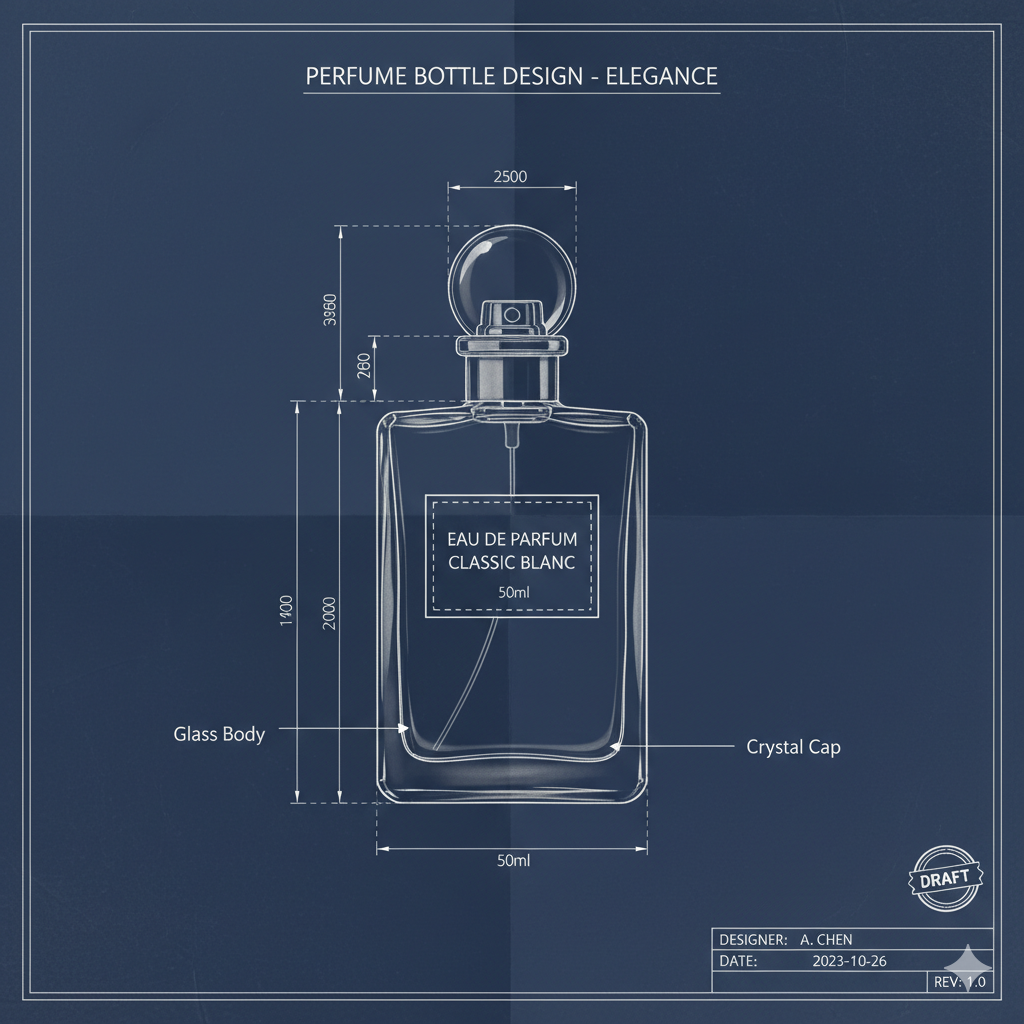

Step 1: The Blueprint

Everything begins with a design. You have two simple ways to give us your design.

- Provide a Physical Sample: Maybe you found a bottle you love, or you have a 3D-printed model. You can just send it to us. Our engineers will carefully measure it and create a professional technical drawing.

- Provide a Design File: If you have a designer, they can send us a 2D drawing or a 3D model. We will review it to make sure it can be manufactured effectively.

Once we have the drawing, we send it back to you for final approval. This is a critical step to ensure every detail is perfect before we make anything physical.

Step 2: The Sample Mold and Prototype

After you approve the drawing, we create a sample mold1. This isn't the final mold for mass production2. It’s a smaller, specialized mold used just for making a few test bottles. This process takes about 20 days. Once the sample mold1 arrives at our factory, we produce the first physical samples of your bottle.

Step 3: The Approval

We then ship these samples to you. Now you can hold your design in your hands for the first time. You can check the weight, the feel, and the look. If it's perfect, you give us your approval. If you want to make small changes, just tell us. We will adjust the design, create new samples, and send them to you again. We repeat this until you are 100% happy with the result.

Step 4: Mass Production

Once you confirm the final sample, we move to the last stage. We create the large, heavy-duty molds for mass production2. These molds are built to produce thousands of your bottles with perfect consistency. Then, we start manufacturing your full order. Your unique bottle is no longer just an idea; it's a reality.

What if you just want to customize an existing bottle?

You like a standard bottle shape, but you need it to look unique for your brand. You worry the customization process might be complicated. It’s actually a very fast and simple process.

Customizing one of our existing bottles with your color or logo is very straightforward. Just give us a Pantone code3 or a color sample. For branding, simply send us your high-resolution logo file4.

Sometimes, you don't need to reinvent the wheel. Many of our clients find that one of our existing bottle shapes is perfect for their needs. This is a great choice because it's faster, more cost-effective, and has a lower minimum order quantity. The bottle is already designed and tested, so we can focus entirely on making it look like your brand. We can add your specific brand color or print your logo directly onto the glass. This is the quickest way to get a high-quality, customized bottle ready for your fragrance. Let’s look at how we handle color and logos separately.

Customizing with Color

A unique color can make a standard bottle instantly recognizable. We can match almost any color you can imagine.

- The Process: You can either send us a physical item with the color you want—like a piece of fabric or a color swatch—or you can give us a universal Pantone color code. Our team then uses this reference to create a colored sample bottle. We send this sample to you for approval. Once you confirm that the color is perfect, we begin production on your full order. It’s a simple, predictable process that ensures you get the exact shade you want.

Customizing with a Logo

Adding your logo is essential for branding. We offer several high-quality methods to apply your logo to the bottle.

- The Process: You just need to send us your logo file, preferably in a vector format like .AI or .EPS. This ensures the print quality is sharp. We'll discuss the best application method for your design and budget. Then, just like with color, we will produce a sample for your approval before we start the full production run.

Here is a simple table to show the different logo techniques we use:

| Decoration Method | Best For | Look & Feel |

|---|---|---|

| Silk Screen Printing5 | Simple, bold logos (1-2 colors) | A painted-on, slightly raised texture. Very durable. |

| Hot Stamping6 | Metallic or foil effects (gold, silver) | A shiny, luxurious, and premium metallic finish. |

| Decal Application7 | Complex, multi-color graphics | A smooth, integrated image that looks like part of the glass. |

| Frosting / Etching8 | Subtle, premium branding | A matte, textured finish that gives the glass a soft look. |

Conclusion

From a completely new mold to a simple logo on a stock bottle, we have a clear process to bring your packaging vision to life.

Learning about sample molds helps in understanding the testing phase before mass production, ensuring quality and satisfaction. ↩

Understanding mass production processes ensures businesses are prepared for the scale and logistics of large orders. ↩

Using a Pantone code ensures color accuracy in bottle customization, crucial for brand consistency and recognition. ↩

A high-resolution logo file ensures the branding on bottles is clear and professional, enhancing brand image. ↩

Silk Screen Printing is a popular method for adding logos to bottles, offering durability and a distinct texture. ↩

Hot Stamping provides a luxurious finish, ideal for premium branding, making it a valuable option for high-end products. ↩

Decal Application allows for complex graphics, offering a seamless look that integrates well with the bottle design. ↩

Frosting or Etching provides a subtle, premium look, perfect for brands seeking an understated yet elegant design. ↩